POWER RANGE

We are able to provide motors with powers up to 1.2MW of power.

Maximum power one of our motors can provide is 1.2MW of peak power and 690 KW of continuous power. This is our biggest AXM4 Triple motor (3 motors AXM4 stacked together in series). Our smallest currently available motor is AXM2 which has continuous power up to 75 KW at 6000 RPMs.

With lower current or voltage input and/or lower motor speed it can be suitable for applications with lower power requirements like small cars and motorcycles.

Customizable option - contact us for customized shafts, customized windings, bearings or temperature sensors. We stand ready to customize and tailor solutions to reasonable needs of our customers.

In case of a high order quantity, we are able to develop and produce a whole new motor from scratch according to customers’ requirements.

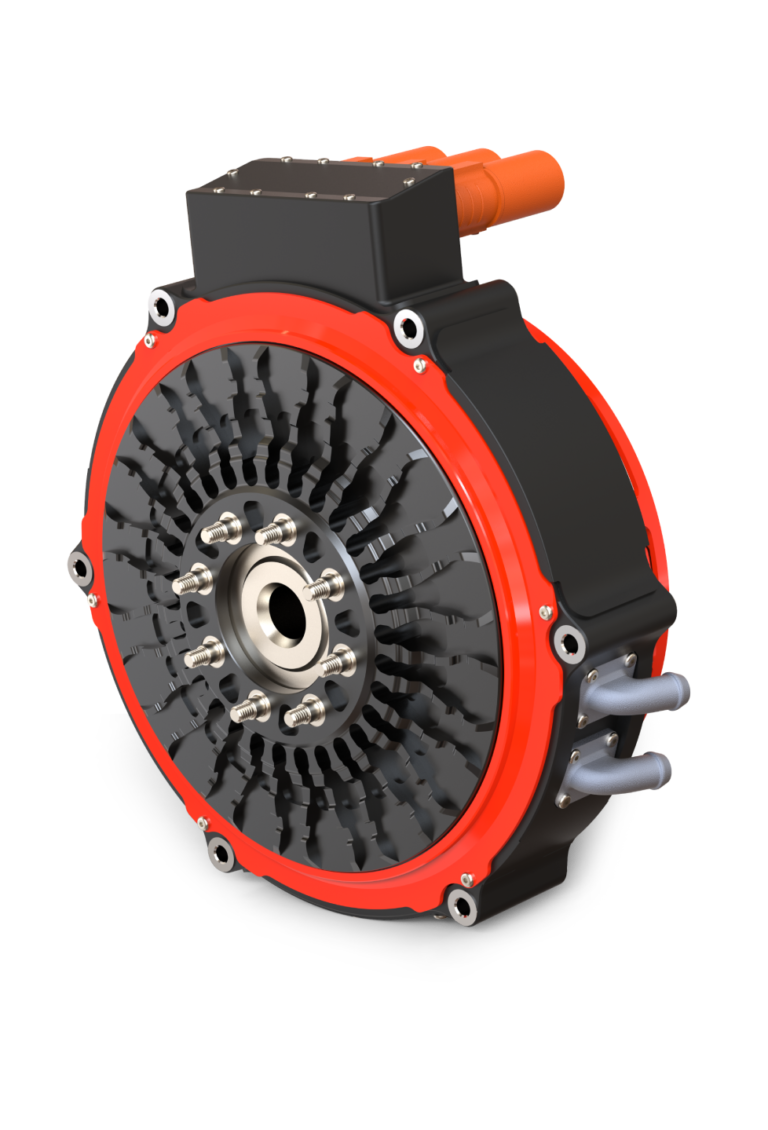

E-MOTORS OF THE FUTURE ARE HERE.

DOUBLE WINDINGS (2 X UVW) – REDUNDANCY OPTION

All of our motors can be provided with a redundancy option – 2 separated winding halves.

This option is recommended in 2 cases:

if one controller cannot provide enough electrical current to enable full power of the motor. In that case, one motor is powered with 2 controllers at the same time.

if a customer desires an additional safety factor. In case of motor’s windings failure, or in case of controller failure, only half of the motor will break and stop working, and the other half will still be able to drive the motor (with half of the power).

In case you choose 2 x UVW motor option, 2 controllers need to drive the motor, each one providing half of the needed current for the motor. In this case you need tandem resolver or encoder signal splitter.